Engineering Services

- INNOVATE, DESIGN, CREATE

About Us

Providing Engineering Services namely R&D, Product Development, Jigs/Fixture Design, FEA, Consultancy, 3-D Modeling/2-D Drafting & Reliability Analysis using all major engineering softwares & inhouse developed standards

Defence & Automobile Expert

COMPLETE PRODUCT DESIGNING

Turning concepts into cutting-edge creations

Vehicle Designing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Weapon Systems

We designed a versatile welding fixture to handle both 4.5-meter-long and 3.5-meter-long aluminum canisters using a unified setup.

Read More

Aluminum’s high thermal conductivity and deformation tendency posed significant challenges, especially for long, continuous butt welds. To address this, we conducted detailed welding simulations using CFD techniques, breaking the 4.5-meter weld into 15 sections to manage heat dissipation and prevent profile distortion. The fixture design included modular components weighing up to 1.5 tons for each of the four welding stages. This approach minimized deformation, reduced production time, and achieved high repeatability. Additionally, the square-shaped canister’s C-profile mating surfaces required precise alignment with flat plates, where we used jig-mounted clamps for stable positioning during welding. This solution delivered cost efficiency and enhanced the client’s production throughput.

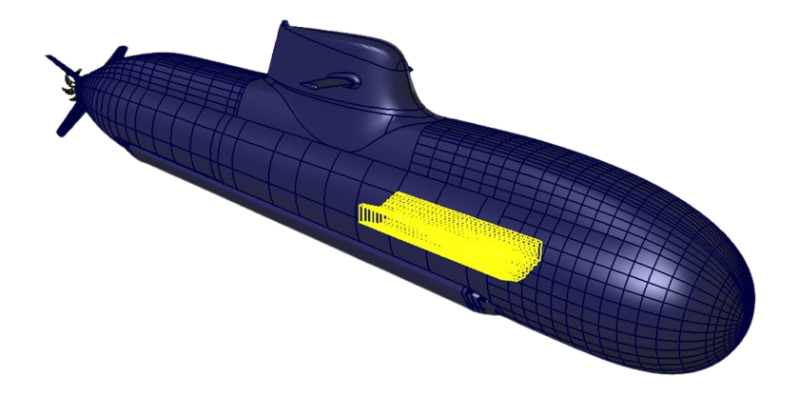

Naval Systems

We designed and developed robust submarine panels, including VFD panels, power supply panels, and junction boxes, for high-performance underwater applications.

Read More

The VFD panels, measuring 1800 mm wide, 1600 mm Page 2 of 2 high, and 400 mm deep, were designed to meet IP56 ingress protection standards and EMI/EMC compliance. Static and dynamic FEA was conducted, simulating a 10G static load and a 5G dynamic load under a half-sine wave profile lasting 30ms. These analyses ensured the panels’ ability to withstand extreme accelerations and vibrational forces during operational deployment. Structural integrity, thermal management, and component layouts were optimized to operate reliably under high humidity, pressure, and mechanical stresses in submarine environments. Our design adhered to defense-grade standards, delivering durable, efficient, and reliable solutions for naval applications.

Vehicle Designing

We engineered a 5.5-meter-long vehicle body mounted on an ISUZU truck chassis, designed to meet stringent CBRN (Chemical, Biological, Radiological, and Nuclear) compliance standards.

Read More

The vehicle body, weighing 7000 kg, incorporates bulletproof glass and a cabin capable of sustaining internal pressure levels between 15-20 bar, ensuring safety in hazardous environments. A key challenge was the vehicle’s height of 3.2 meters, which posed a critical risk of toppling during operations. To address this, we performed detailed stability and weight distribution analyses, optimizing the center of gravity by positioning heavier components closer to the base. Advanced FEA techniques were employed to assess the structural integrity under dynamic driving conditions. The result is a stable, safe, and robust vehicle suitable for defense applications in challenging terrains.

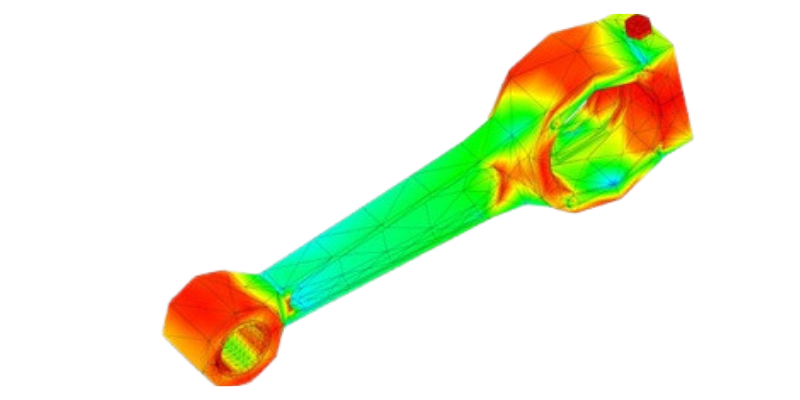

Finite Element Analysis

We performed comprehensive structural and dynamic analyses to optimize defense vehicles for operational performance and durability.

Read More

Multi-body dynamic (MBD) simulations were conducted to evaluate the vehicle’s maximum safe speed, cornering performance, and damper and leaf spring responses over potholes. Structural analysis at 3G acceleration and modal analysis were performed to ensure durability and resistance to vibrational frequencies encountered during operation. Door sagging analysis for 120 kg doors validated hinge designs for prolonged use without deformation. Additionally, our MBD analyses helped refine vehicle dynamics for stability, comfort, and safety under real-world conditions, ensuring the vehicle meets JSPenta5 standards and surpasses operational performance expectations.

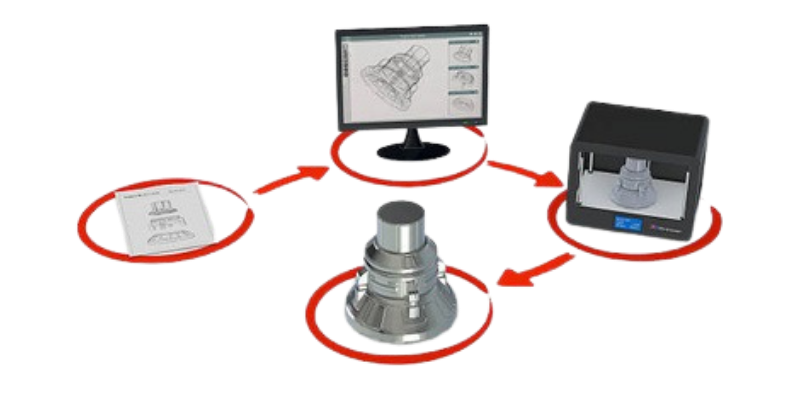

Product Development

We designed various products like medicine bottles & equipment with various shaped. We did product design, prototype development and serial manufacturable design.

Our Specialization

Defence & Automobile Expert

Argan Technology Services Pvt. Ltd., we offer a comprehensive range of engineering services that leverage cutting-edge technology, domain expertise, and a commitment to excellence to deliver tangible value to our clients.

Our Strengths

- Decades of Relevant Industry Experience Holding multiple patents

- Expert Team

- Well Versed with Customer Requirements

Our Speciality

- Set Processes

- On-Time Delivery

- Project Management

- Data Security

- High Speed Machine

- Customer Centric

Our Expertise

- Solidworks

- Thermnet

- Hypermesh

- Solidedge

- Fusion360 AutoCAD Ansys

- UGNX

OUR SERVICES

OUR SERVICES

Argan Technology Services Pvt. Ltd., we offer a comprehensive range of engineering services that leverage cutting-edge technology, domain expertise, and a commitment to excellence to deliver tangible value to our clients.

- Product Design & Engineering

- Product Optimization 3D CAD

- Modeling & Drafting Jigs & Fixture Design

- R&D with DMAIC / DMEDI FEA Services Reliability Analysis & DFMEA Solar Structures

Our Proficiency

Transmission

Gear, Clutch, Shafts, Bearings, Gearbox arrangements, Final Reduction, Braking arrangement.

Hydraulics

Hydraulic component design, Hydraulic system Design & simulations and Pneumatics.

Electrical

Electrical Panel Design, Ruggedized Design, Harnesing in 3D.

Mechanics

1D/2D/3D mechanical, Cam and followers, Powertrain, Vehicle dynamics.

Consultancy

Optimization of cost/weight of structures, Reliability Analysis, Patents, Manufacturing Support

Our Major Project Deliveries-

- CBRN Compliant Military Vehicle

- QRSAM, VLSRSAM

- Military Bridges

- Systems for Artlilary Towed Guns

- Air Independent Propulsion (Submarine)

- Electrical Panels for Naval Systems

- Ekectrical Harnesing for SLV

Our Clients